Latest Photo

Here is an update. I posted this on facebook but I realize that not everyone uses facebook. This is the finished railing. Did some painting since this picture. Its raining today and I will work on some rough electrical.

Yup its raining in june…Just like it rained in July when my roof was opened up…

Finishing Stair Treads

applying clear coat finish to the treds

That is “finishing” as in applying a finish, not to imply that they are finished yet.

Since I don’t have much space inside I wait for nice weather to do finishing of the stair treads on my quiet dead-end street.

I hose off the street a bit to keep dust at a minimum. The finish is applied by a painting pad instead of a traditional brush. Its impossible to leave any brush strokes when you are using a pad and a roller can create texture and bubbles.

Here is the previous post with information on the stair tread material.

Getting Ready for the Wood Stove

tile area for the wood stove

I’ve actually bought the wood stove seen in my earlier post and it sits in the middle of my entry waiting for the stairs as the method for getting it’s 300 pounds of cast iron up to the second floor.

This image shows the tile work that is going to be underneath and behind the wood stove. In the foreground is a small piece of the oak flooring that will meet the tile floor.

The Railing for the Deck

deck view from the inside

I have finished enclosing the deck area with wood and glass. The wood railing design is very much as described earlier.

A rendering of my concept

I talked about this design in my earlier post entitled : “Details, details”

This new railing relates somewhat to the garden fence below. I used the same design techniques outlined in the process of creating that fence here : fence design

View from the Street

deck view from the street

The deck enclosure uses three different materials which may be considered taboo by some architectural aficionados. While I’ll be the first to admit that I tend to over think this stuff, there are practical reasons here. The stucco is a “fire wall” required by code due to the close distance to the property line.

The glass area was created to maintain the view that I was enjoying from the unfinished railing and the angled wood was a response to watching the sun set.

A Custom Glass Railing

aluminum and rubber design

I wasn’t able to find any “off-the-shelf” solutions to capture the tempered glass railing. I found the parts that I needed from two different sources.

I added rubber strip material to an aluminum “U” extrusion to create a way to capture the glass.

Aluminum is a beautiful material and can be worked with standard woodworking tools.

cutting aluminum

drilling and countersinking

extrusion attachment

The only difference working aluminum is that the sawdust sparkles.

aluminum sawdust

A Follow Up on Heating Registers

I was looking for registers in a previous post about “Life in the crawl space.” The register is the final frosting on the cake for all that nasty work down below. I found these bronze fixtures at a fairly reasonable price. The bigger they get, of course, the more they cost so I went with a less expensive register for my 12″ x 12″ Floor Return. I have to save money somewhere.

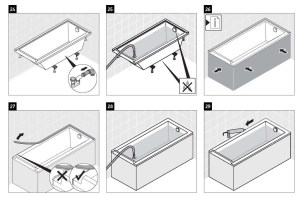

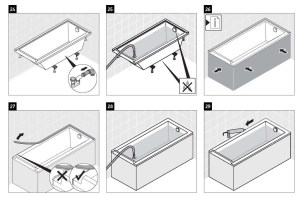

The Tub has Arrived

"onto" by duravit

But not the tub I originally wanted. My goal was to have a deep soaking tub that also functioned well as a shower. I thought I found that when I wrote the post about the Duravit “Seadream.” By the time I was ready to order it was out of production. The “Onto” is a beautiful and deep tub but it doesn’t have as much standing space as the other one did.

Now I just have to figure out how to install it ??

duravit installation guide